UHM CNC Horizontal Machining Center Inquiry

> UHM Center-Mount Spindle Head (Single / Twin Station)

-

Features:

- Roller type linear guideways on 3 axes in combination with highly rigid machine structure exhibit outstanding machining accuracy.

- X, Z-axis are transmitted through oversized ball screw of Ø80 mm. Y-axis employs Ø63 mm, class C3 high precision ball screw with feature of high rigidity.

- 3 axes are equipped with Schneeberger linear guideways and linear scales, thus ensuring accurate positioning accuracy.

-

MODEL UNIT UHM-1250TW UHM-1250TWA UHM-1416TW TABLE Table Size mm 1250X1250 1250X1250 APC 1400X1600 T-slots Size mm 22X7 24X7 Maximum Load kg 5000 8000 Indexing Degree 1゚(0.001゚) TRAVEL X-Axis mm 2000(2500) 2000 Y-Axis mm 1600(2000) Z-Axis mm 1200(1600) W-Axis mm 400(500) 500 SPINDLE Spindle Speed rpm 2500(4000) Spindle Taper 7 / 24 taper ISO.50, BT-50 DISTANCES Spindle Center to Table mm 0-1600(2000) Spindle Nose to Table Center mm 100-1700(2100)(-50~1650(2100) 100-1700(2100) Hight From Ground to Table Surface mm 1350 FEED RATE Rapid Feed Rate X / Y / Z / W m/min 15/15/15/10 Minimum Setting mm 0.001 Cutting Feed Rate mm/min 1~5000 MOTOR Spindle Motor - cont. / 30min. kW 15/18.5(22/26) X / Y / Z / W / B-Axis kW 4/7/4/4/4 7/7/4/4/7 Lubricator Motor kW 0.15 Hydraulic Pump kW 2.25 Coolant Pump kW 1.62 Chip Conveyor kW 0.25 Oil Cooler Pump kW 3.6 ATC No. of Tools pieces 40(60) Tool Selection 任意式(絕對式) Max. Tool (dia. / leng.) mm Ø125/Ø250(Without Adjacent Tool)/Length 400 Max. Tool Weight kg 18(25) MISCELLANEOUS Power Required kVA 45 50 Compressed Air kg/cm² 6 -

standard accessories:

- Linear scale on X, Y, Z-axis

- Spindle oil cooler

- Automatic power off

- Hydraulic system

- Coolant system

- Lubricator system

- Alarm lamp

- Work lamp

- M. P. G.

- RS-232 interface

- Heat exchanger

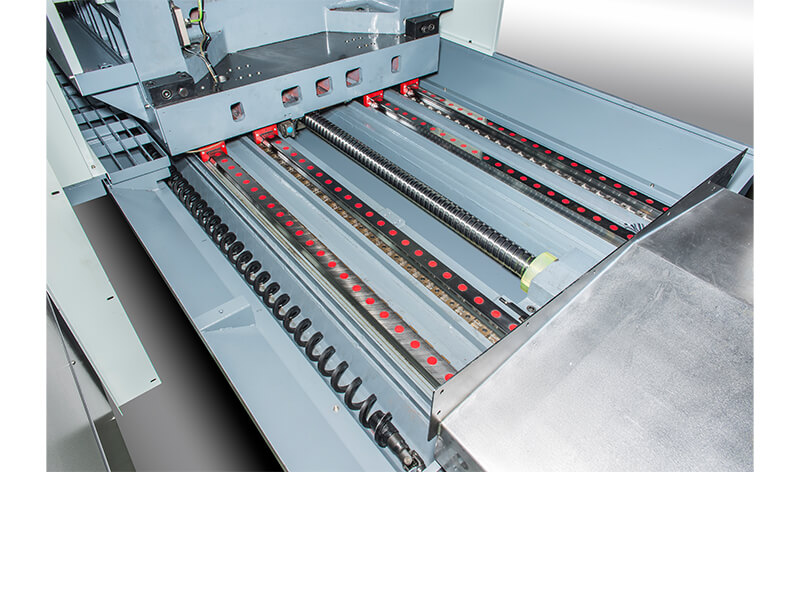

- Chip conveyor and cart

- Leveling bolts and pads

- Controller manuals and circuit diagram

- Operation manuals

- Machine inspection lists

- Fully enclosed splash guard

- Toolbox with spanners & wrenches

- FANUC 0iMF controller

- ATC: 40 tools (swing arm type)

optional accessories:

- ATC: 60/90/120 tools (swing arm type)

- 24/32 tools ATC (side mount type)

- Oil mist device

- Variety of controllers ( FANUC / Mitsubishi / SIEMENS / HEIDENHAIN / FAGOR )

- Various auxiliary work tables

- Air conditioner at electrical cabinet

- Coolant through spindle

- 0.001° indexing on B-axis (Simultaneous machining)

- Tool measurement device

- Workpiece centering measurement device

- Chip auger on Z-axis

- Coolant jets around spindle (independent pump)

- Various sizes of table

- Semi-enclosed splash guard